A Breakthrough in Agile Perception: The Design Behind SYNCROBOTIC’s Lifting-Head Quadruped Robot

2025-06-12

SYNCROBOTIC Launches AI Robot Platform in Taiwan, Pioneering Physical AI in Smart Security and Inspection

2025-06-17How AI is Powering the Future of Predictive Maintenance

Imagine a world where equipment failures are prevented before they happen. No more surprise downtime, no frantic rush for repairs—just seamless operations powered by foresight. Thanks to advances in AI, IoT, and machine learning, that vision is becoming a reality.

In this post, we explore how a unified AI-powered architecture—combining edge computing, large language models (LLMs), and smart algorithms—is transforming predictive maintenance across industries.

The Intelligence Behind Predictive Maintenance

At its core, AI-based predictive maintenance aims to anticipate equipment failures and optimize maintenance schedules. This is achieved by collecting and analyzing data in real-time to detect anomalies and forecast potential issues.

The process typically follows these steps:

1. Define the Outcome

Start by identifying the goal—such as predicting the Remaining Useful Life (RUL) of critical assets.

2. Inventory the Data Sources

Map all available data inputs: sensor logs, maintenance history, usage patterns, and more. Not all data is essential, but the right mix increases accuracy.

3. Capture and Consolidate Data

Integrate data from diverse sources—machine sensors, vision systems, and operational logs—into a centralized platform.

4. Build, Test, and Iterate

Use statistical and machine learning models to identify patterns. Iterate rapidly to refine accuracy and uncover unexpected failure signals.

5. Validate in Real-Time

Deploy the model on live data streams to evaluate performance under real-world conditions.

6. Operationalize and Evolve

Integrate the AI output into your existing systems, adjusting maintenance workflows and resources dynamically. Continuously learn and improve based on ongoing feedback loops.

A Glimpse into the System Architecture

The success of predictive maintenance hinges on a robust technical backbone. Here’s an overview of a typical end-to-end architecture:

🔹 Edge Devices

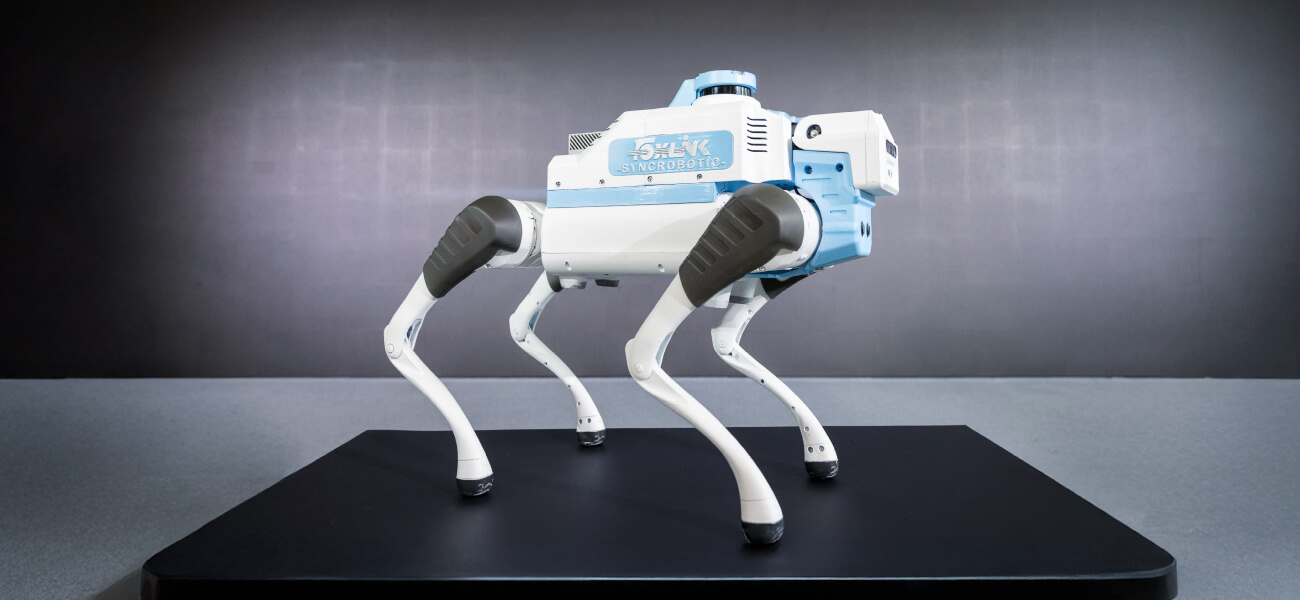

Smart sensors and embedded systems (like the Sync Dog) capture real-time data from the field.

🔹 IoT Hub

Acts as a data bridge between edge devices and cloud infrastructure.

🔹 Event Hub + Stream Analytics

Processes high-volume data streams in real time, flagging anomalies and trends.

🔹 Storage + Databases

Blobs and DocumentDBs archive historical and structured data for deep analysis.

🔹 LLMs and Vision Algorithms

These AI engines combine linguistic and visual intelligence to enhance interpretation and decision-making. They power advanced models that detect subtle signals often missed by traditional methods.

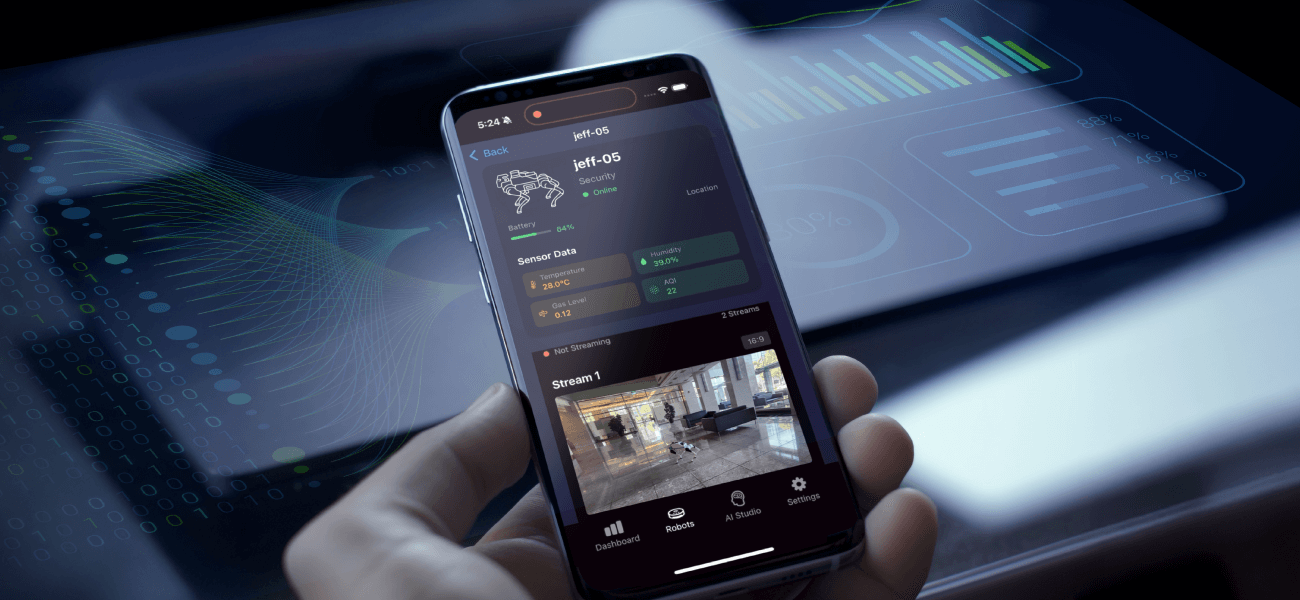

🔹 Web/Mobile Applications

User interfaces provide dashboards, alerts, and collaborative tools. Native apps on iPad, iPhone, Android, and Windows allow teams to monitor and act from anywhere.

Figure 1. The process architecture of AI predictive maintenance

Cross-Platform Dashboard Management

At the center of this ecosystem is the SYNC AI Dashboard—your single point of command for asset health and predictive insights.

- Native apps for iPad, iPhone, Android, and Windows devices.

- Real-time alerts for important changes in your data.

- Collaboration tools to share information with colleagues and take immediate action.

- Unified experience across Windows, iOS, Android, and any HTML5 browser.

Whether you’re on the production floor, in the field, or in the office, the SYNC AI Dashboard ensures that critical insights are always within reach, on any device.

Visual + Language = Smarter Decisions

The true power of this solution lies in the synergy between vision-based algorithms and LLMs. Together, they boost:

- Accuracy of issue detection

- Efficiency in root cause analysis

- Intuitiveness of decision support

This hybrid AI approach doesn’t just generate insights—it tells you why something might fail and what you should do next.

Final Thoughts

AI-powered predictive maintenance is more than a technical upgrade—it’s a cultural shift toward proactive, intelligent operations. Businesses embracing this transformation are seeing improved uptime, reduced costs, and empowered teams.

Whether you’re in manufacturing, logistics, or critical infrastructure, the time to modernize your maintenance strategy is now.